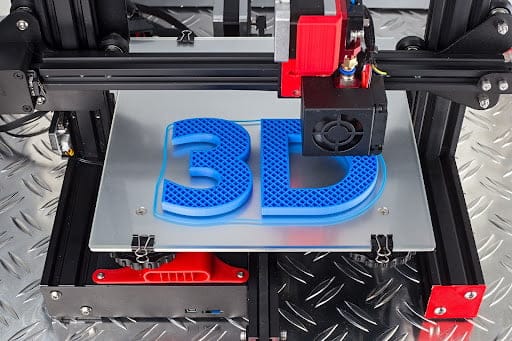

The 3D printing process, also known as additive manufacturing, is a process that takes advantage of additive processes to make three-dimensional solid objects. 3D objects are created from digital files using an additive process where a successive material layer is laid down until the intended object is formed. Each layer of material is a thinly sliced cross-section of the to-be object.

In contrast, a 3D printing catalog online is different from subtractive manufacturing, which is basically hollowing or cutting out a metal or plastic piece using a machine like a milling machine. Because of that, 3D printing technology is widely used, especially in automotive and manufacturing industries, to make parts and tools using 3D printers. Also, its popularity has grown because the technology uses less material than traditional manufacturing methods and can produce complex shapes. To understand more about 3D printing, check out below how it works.

Table of Contents

The Working Principle of 3D Printing

The whole 3D printing process starts with a 3D model, which can be created or downloaded from a 3D library. As stated earlier, 3D printing involves a process called additive manufacturing, which uses CAD (computer-aided design). Therefore, a 3D printer will only create the intended object layer by layer with the help of a computer program.

3D printers come in different shapes, sizes, and types, each working slightly differently from the other. However, despite the difference in functionality, size, and shape, the basic concept of how 3D printing works starts by designing the object on a computer. 3D printers use incredibly precise modeling software that only creates what was designed on the computer. Rhino is among the top 3D printing programs used in the industry.

The material comes out in thin slices when printing something on a 3D printer. Each slice will stick to the other to form the designed object from the bottom up. Also, each layer has its own purpose and can be as complex as having wheels, hinges, or moving parts. The process will continue and repeat until the model is full (according to the initial design).

Since the first 3D printed object was made back in the 80s (1), the 3D printing sector has grown exponentially with many possibilities. One of the mysteries in this field was the type of “ink” to be used and since then, different materials have been used, from the thermoplastic filament (main one), metals, powder, resins, and plastics. The thermoplastic filament is preferred due to its durability and flexibility.

What is a 3D Printer?

A 3D printer is a device or machine that uses CAD to create three-dimensional solid objects from various materials like powder or molten plastic. They come in various sizes and shapes, ranging from large construction models (used in making 3D-printed houses) to equipment that fits on an office table. 3D printers come in three main types, each using a slightly different method.

Common 3D Printer Types

- Selective Laser Sintering (SLS) printers. They have a laser for sintering printing material or polymer powder particles into an already-built solid part.

- Stereolithographic (SLA) printers. They are built with a laser that can form liquid resins into plastic.

- Fused Deposition Modelling (FDM) printers. They are the most common type of 3D printing machine. They form objects one layer after another using the hot nozzle that melts the thermoplastic filament as it passes down in the form of thin slices.

What Can You Print With A 3D Printer?

The best thing about 3D printing is that it is flexible in terms of what can be printed. For example, 3D printers can print rigid materials like hangers and sunglasses using plastic. Also, they can create complex and flexible objects like bike handles and phones using plastic powder and hybrid rubber.

Other 3D printers have the ability to use metallic powder and carbon fiber to create extremely strong industrial parts. Some of the common 3D printing applications include:

- Rapid prototyping and manufacturing

- Production of highly durable and reusable tools

- Functional parts production

- Production of inexpensive models in medicine, architecture and education

Conclusion

3D printing, as compared to traditional crafting, will only create what is designed in the computer program. This means that you can only print a 3D object using the material you fed in the printer. The best thing about this type of production is that it reduces waste, causing a more positive environmental ripple effect and building more sustainability within businesses.

This article is very nice and I liked it, thank you for the article.